Strength, vibration-resistance and single-sided assembly.

Why automotive designers choose FDS!

Demanding application stresses demand an innovative yet proven fastening technology. Today’s ‘build lighter, build stronger’ body-in-white assemblies deploy composite designs where different material types need to be joined together with ease - and provide longevity of performance. That means one-sided accessibility and removability of the fastener is of paramount importance and a major advantage – especially where recyclability is a prerequisite.Innovative thread geometry

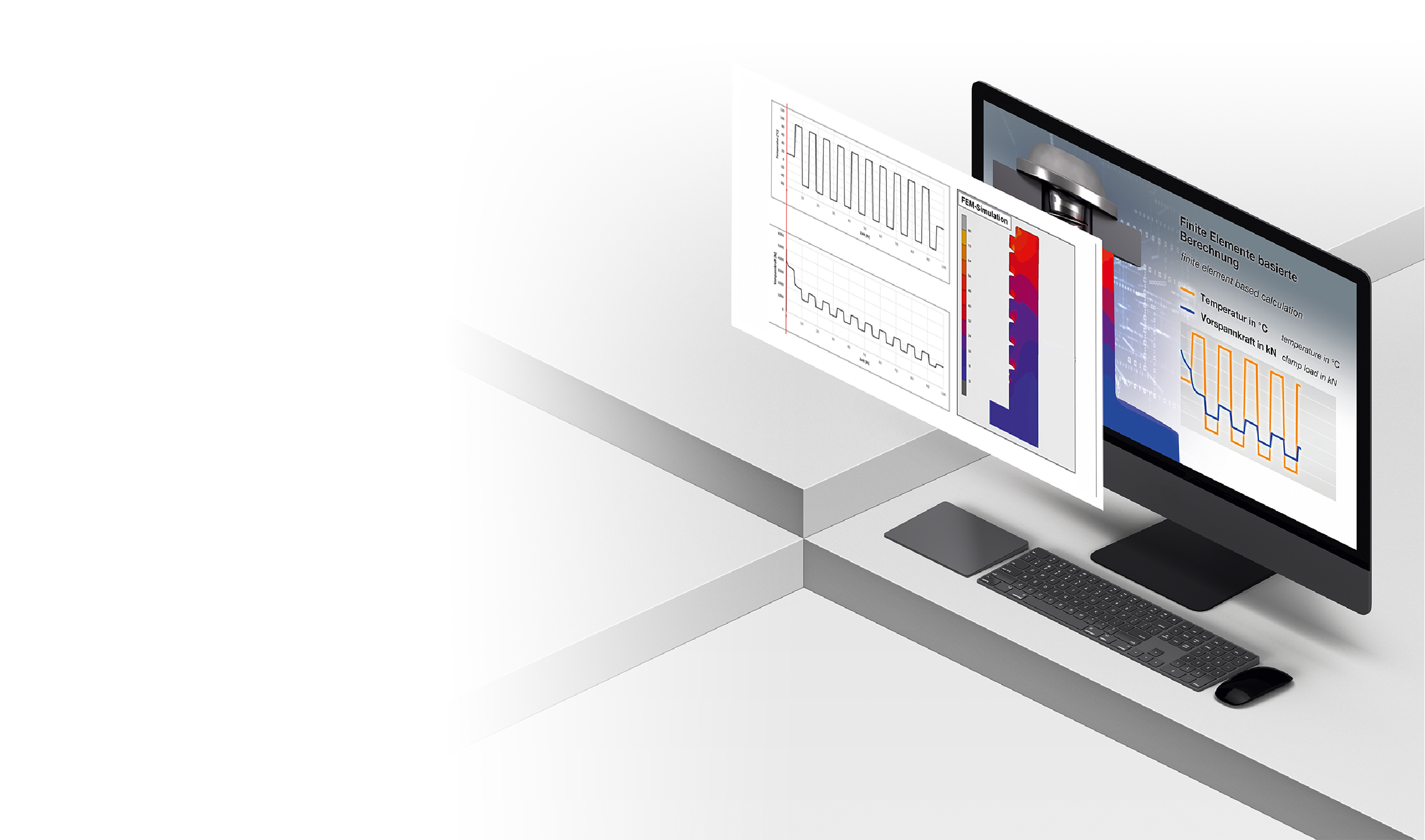

EJOT FDS® (flow drilling screw) fastens thin sheet steel and aluminium without the need for a pilot hole, and creates an incredibly high-strength joint from single-sided access situations, for assembly into hollow profiles. It is a six-stage process; heating, penetration, through-draught formation, thread-forming, full thread engagement and finally tightening.

The geometry of the FDS® design means it accommodates the small amount of the displaced material that flows against the fastening direction which in turn means the clearance hole is free from debris. Instead, this material is absorbed into a void below the actual screw head.

Genuine cost and performance benefits

Without the need for punching or pre-drilling of a pilot hole, the EJOT FDS® joining process is considerably faster and delivers a more efficient automated assembly. The material assembly order when fastening without a pre-hole should be ‘thin on thicker’ or ‘soft on hard’ respectively. This way higher tightening torques can be achieved and the gaps between two components minimised. The result is a screw joint that is able to transfer high pull-out as well as shearing forces, assembled quickly from one side, without the need counter support!