No two days are ever the same

The UK APPLITEC Centre

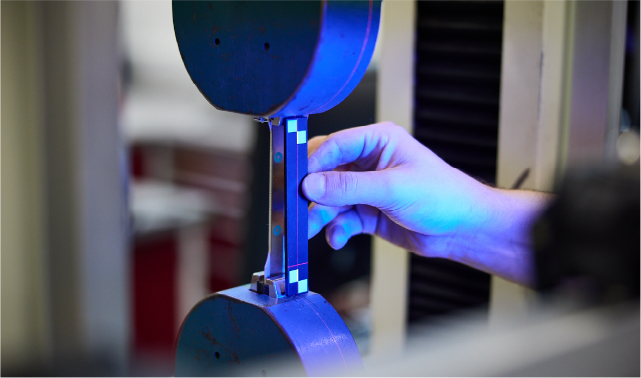

EJOT UK’s Applitec Centre is the UK’s foremost fastening technology laboratory, equipped to support the development and testing of products that span all our market sectors from building envelope and safety-critical anchoring to advanced industrial engineering. It’s a solutions-based hub where design and testing, work hand in hand with quality processes and application-based learning.

For customers with conundrums to solve, the lab is an agile resource that supports quick response. In a similar way, our team has a first-class reputation and impressive backstory when supporting OEMs, especially at the conceptual stage of system design.

Working in tandem with the highly impressive TEC Center in Germany, the UK laboratory goes beyond R&D to bring genuine value to partnerships, maintain quality systems, and deliver responsible training aligned to industry best practice.