EVO PT - Constant installation torque with variable installation depths

How EVO PT® delivers cost and performance benefits in one evolution!

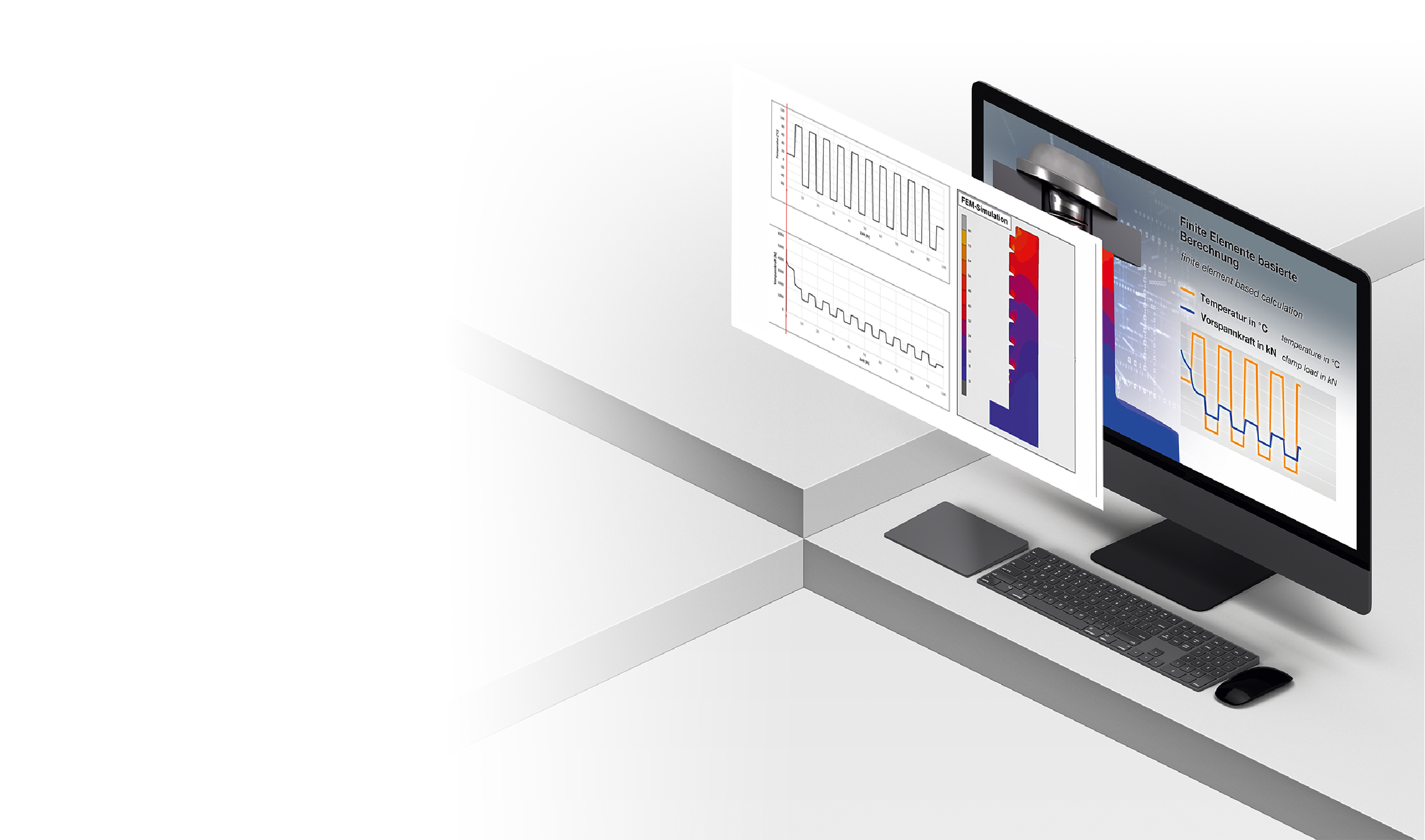

The EJOT EVO PT® represents the latest innovative chapter from the originators of direct fastening into thermoplastics. An evolutionary development from the PT and Delta PT line, EVO PT® integrates real time manufacturing and application knowledge with new methods based on physical computer simulations, within the development process. The result is a next generation fastening solution that sets new standards offers design engineers many new possibilities.

Innovative forming thread

The unique lead-in thread of the EVO PT® allows for easy and straight positioning. Self-alignment means the screw centres automatically in the pilot hole during the installation, creating a uniform load on the thread flanks when completely fastened.

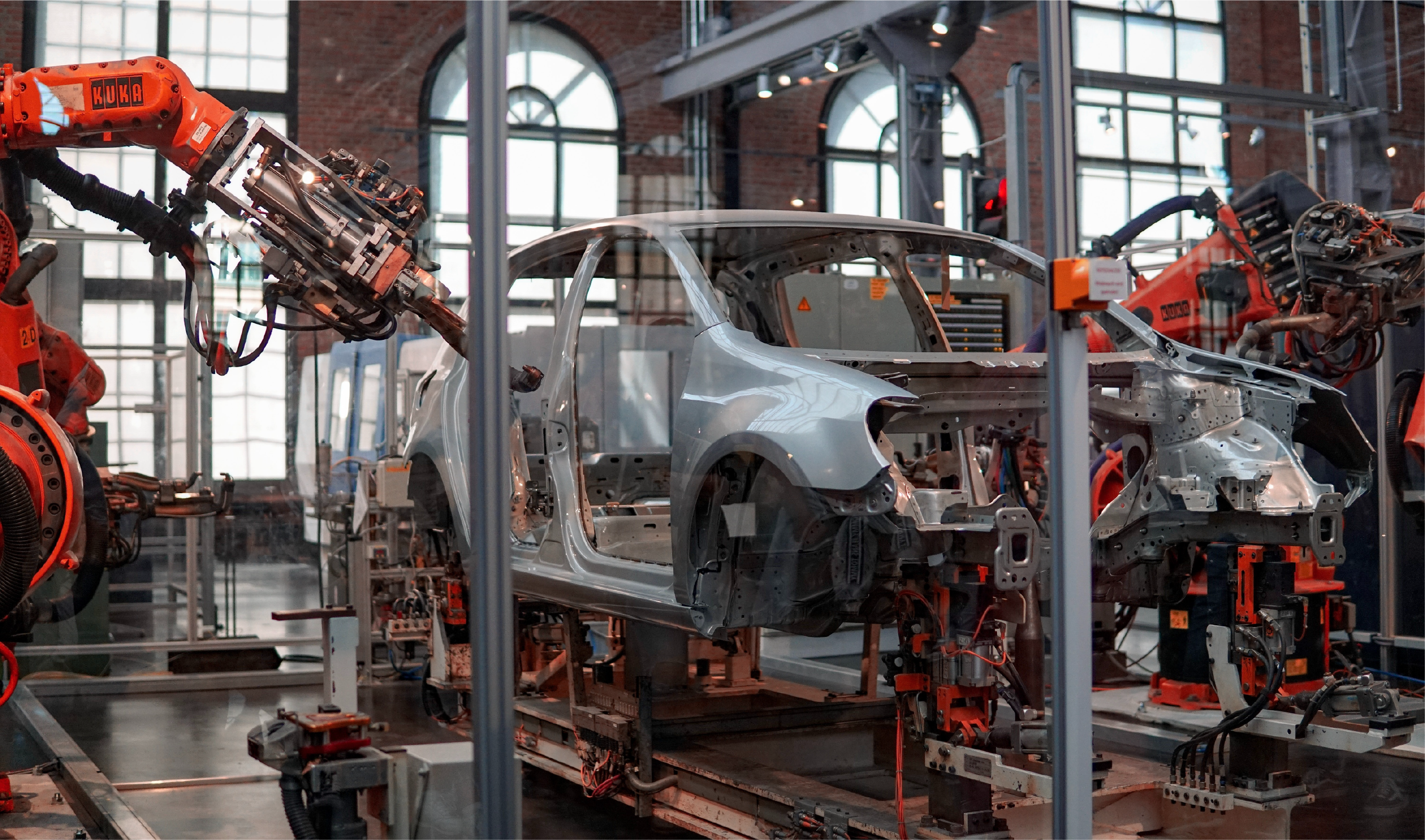

Genuine cost and performance benefits

In turn, these exciting characteristics mean that during the thread-forming process, the torque curve created during the installation phase is virtually independent of the screw-in depth. As a result, a uniform tightening torque can be used in application, at different screw lengths. In turn, this can mean smaller installation spaces, or the standardisation of fastener lengths and tightening torques. These features alone deliver key advantages that range from the procurement inventory through to installation processes. Genuine cost considerations aligned to high performance fastening!