Fasteners for lighting in Electric Vehicles

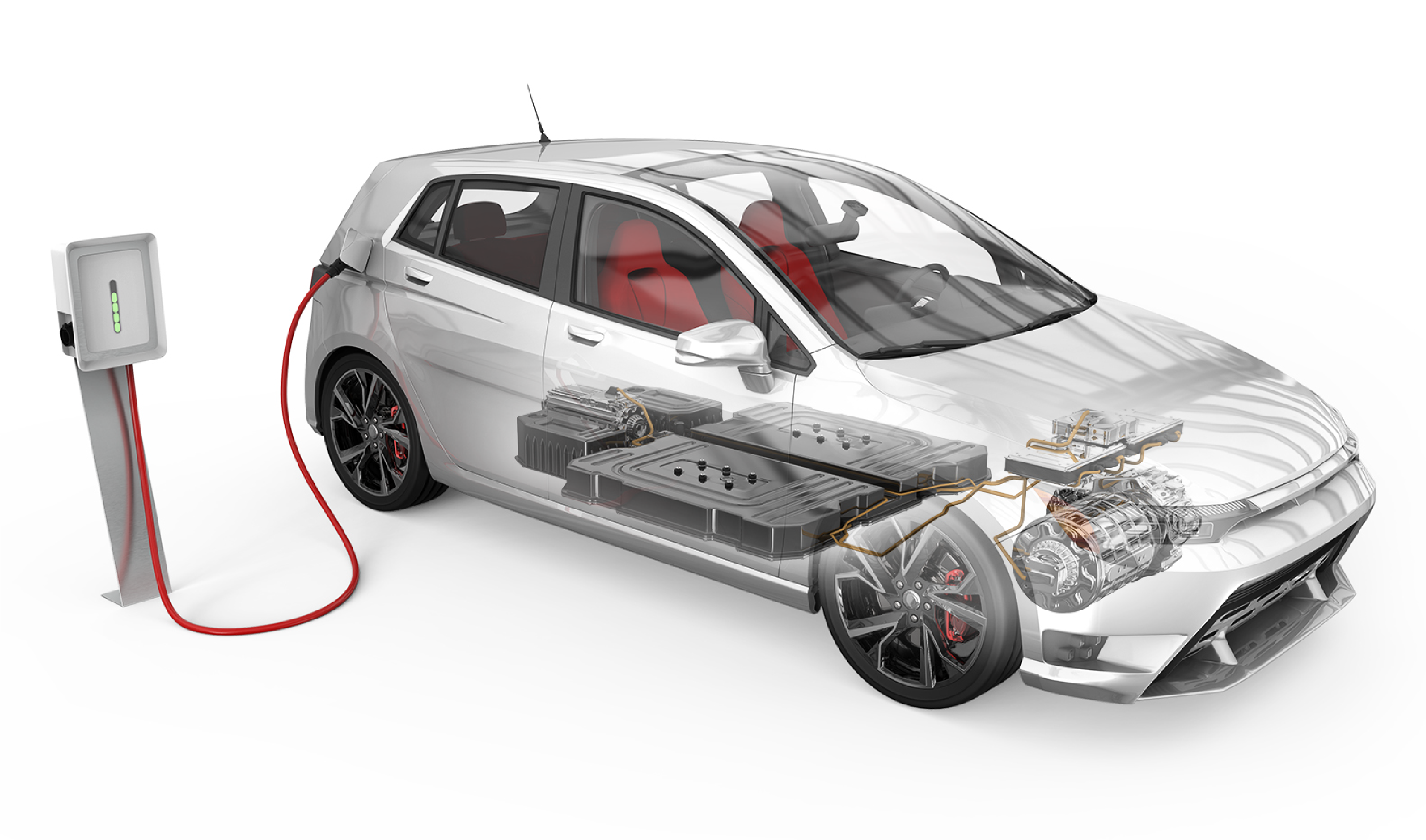

The role of automotive lighting, particularly headlamps and tail lamps, has been put centre stage with the evolution of electric vehicles. In fact, automotive lighting design and innovation is enjoying a new lease of life due to the important contribution that alternatives to halogen lights can make to the energy efficiency, weight and styling of vehicles.

Today’s increased demand for LED lighting in particular follows a gradual shift to this technology over the last two decades. It is a process that EJOT has helped facilitate through our range of fastening systems for fixing car headlights, tail lights and interior lighting, as well as numerous other vehicle lighting applications, which is why our products already feature in many of the cars, vans and commercial vehicles we see on the roads today.

Bolstered by the green, sustainable potential of EVs, driven by governments around the world who seek to phase out internal combustion engine (ICE) vehicles over the next two decades, LED lighting is becoming the norm in vehicle design. But along with the great opportunities that LEDs present, incorporating this technology effectively can present challenges for vehicle designers.

Lower energy consumption

The key benefit of LED lighting in EVs is their low energy consumption versus other types of lights. This means reduced demand on the power stored in the battery to assist with maximising range. So finding effective ways to incorporate LED lighting to a structurally robust and operationally reliable standard is crucially important.

Lightweight construction

LEDs can be designed in a way that means they can offer equivalent – or improved – performance versus other types of lighting at a lower overall weight. Again, this helps optimise the EV’s battery range. Any headlight adjusting screw assemblies, therefore, should seek to utilise fasteners which enable the use of lightweight materials.

Increased styling and aesthetic potential

Using LED lighting in EVs has enabled designers to adopt often radical styling which in many cases clearly distinguishes the latest generation vehicles from those which are ICE or hybrid powered. Eye-catching design of the lighting, in common with many other vehicle features, is dependent on being able to build lighting assemblies to a robust standard and ensure attachment to the vehicle is both secure and hassle-free.

EJOT has a wealth of experience and expertise in automotive lighting to help you achieve your EV design goals. In conjunction with our automotive lighting aiming mechanism and device specialist ASYST, we have a range of fastening solutions that is perfectly aligned to the needs of EVs.

Multiple ASYST products all can be combined with EJOT products to providing easy to install / build methods. All offer a quality solution for vehicle lighting with guaranteed performance thanks to the rigorous design and testing process undertaken by EJOT’s fastening engineers.

One of the most utilised EJOT solutions within lighting assemblies is EJOFORM. This is EJOT’s unique multi-stage cold forming process which enables the creation of high quality fastening elements in steel, aluminium or partly copper, capable of performing multiple functions in one application. Every EJOFORM product is bespoke to the application, enabling automotive designers to maximise joint strength, save cost through parts reduction and optimise application.

Other products within the EJOT portfolio used within automotive lighting include the Delta PT, an advanced screw for direct fastening into thermoplastics and ALtracs Plus, a self-tapping screw for light metals.

Automotive lighting designers also benefit from EJOT EASYboss. This is a range of plastic fastening elements – compatible with the Delta PT screw – that can be used in the assembly of materials with varying thicknesses, which means less reliance on metal clips.

Today’s increased demand for LED lighting in particular follows a gradual shift to this technology over the last two decades. It is a process that EJOT has helped facilitate through our range of fastening systems for fixing car headlights, tail lights and interior lighting, as well as numerous other vehicle lighting applications, which is why our products already feature in many of the cars, vans and commercial vehicles we see on the roads today.

Bolstered by the green, sustainable potential of EVs, driven by governments around the world who seek to phase out internal combustion engine (ICE) vehicles over the next two decades, LED lighting is becoming the norm in vehicle design. But along with the great opportunities that LEDs present, incorporating this technology effectively can present challenges for vehicle designers.

Lower energy consumption

The key benefit of LED lighting in EVs is their low energy consumption versus other types of lights. This means reduced demand on the power stored in the battery to assist with maximising range. So finding effective ways to incorporate LED lighting to a structurally robust and operationally reliable standard is crucially important.

Lightweight construction

LEDs can be designed in a way that means they can offer equivalent – or improved – performance versus other types of lighting at a lower overall weight. Again, this helps optimise the EV’s battery range. Any headlight adjusting screw assemblies, therefore, should seek to utilise fasteners which enable the use of lightweight materials.

Increased styling and aesthetic potential

Using LED lighting in EVs has enabled designers to adopt often radical styling which in many cases clearly distinguishes the latest generation vehicles from those which are ICE or hybrid powered. Eye-catching design of the lighting, in common with many other vehicle features, is dependent on being able to build lighting assemblies to a robust standard and ensure attachment to the vehicle is both secure and hassle-free.

EJOT has a wealth of experience and expertise in automotive lighting to help you achieve your EV design goals. In conjunction with our automotive lighting aiming mechanism and device specialist ASYST, we have a range of fastening solutions that is perfectly aligned to the needs of EVs.

Multiple ASYST products all can be combined with EJOT products to providing easy to install / build methods. All offer a quality solution for vehicle lighting with guaranteed performance thanks to the rigorous design and testing process undertaken by EJOT’s fastening engineers.

One of the most utilised EJOT solutions within lighting assemblies is EJOFORM. This is EJOT’s unique multi-stage cold forming process which enables the creation of high quality fastening elements in steel, aluminium or partly copper, capable of performing multiple functions in one application. Every EJOFORM product is bespoke to the application, enabling automotive designers to maximise joint strength, save cost through parts reduction and optimise application.

Other products within the EJOT portfolio used within automotive lighting include the Delta PT, an advanced screw for direct fastening into thermoplastics and ALtracs Plus, a self-tapping screw for light metals.

Automotive lighting designers also benefit from EJOT EASYboss. This is a range of plastic fastening elements – compatible with the Delta PT screw – that can be used in the assembly of materials with varying thicknesses, which means less reliance on metal clips.