EPPsys TSSD

Specification

-

Overview

- Fastening element and process specifically for sandwich elements

- Broad application range

- Especially suitable for honeycomb structures

- High transmittable tensile forces

- No corrosion

- Can be used as screw boss or as direct fastening element

Sebastian Schrodt

Head of Sales EJOWELD

Help, guidance and technical support

Your contacts for industrial fastening systems

EJOT’s advanced fastening systems are found in countless industrial and engineering assemblies around the world. Click below for sales and technical support from one of our experienced team. We conduct inspections and observations onsite, in addition to providing help and advice direct from our UK manufacturing centre.

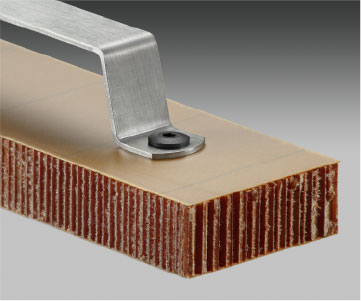

The EJOT TSSD® thermal adhesive bonding boss

The EJOT® TSSD (thermal adhesive bonding boss) product and corresponding joining process have been developed to join components where one is made of fibre-reinforced plastics. The process is suitable for sandwich elements with honeycomb and foam core structures (where they have different top coats) as well as for CRP (carbon reinforced plastic) and GRP (glass reinforced plastic) materials. It is a joining process which involves a plastic boss (made of thermoplastic) being installed into the plastic component with a certain rotation speed and axial load.

How TSSD provides an alternative

Joining components to lightweight honeycomb material has traditionally been achieved through the deployment of potted inserts, also known as ‘wall panel inserts’ or ‘floating inserts’. These can be used anywhere that a fastener is needed, particularly where blind holes that do not pass all the way through the panel are required or where inserts must be “flush” with the panel skin. EJOT, however, has developed an alternative solution for these super-strong, lightweight materials with TSSD. The result is a product range that has simplified and accelerated the fastening process by eliminating surface preparation, can be used as a screw-in boss or as a direct fastening element, and in many cases eliminates the need for any pre-hole.

Wide variety of application potential

EJOT TSSD is suitable for any application where a lightweight composite material is chosen for the purposes of weight reduction without compromising strength, including:

- Automotive

- Aerospace

- Furniture

- Construction

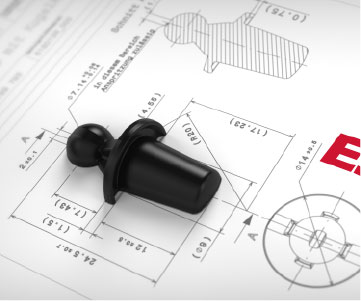

EJOT TSSD® as snap-fit solution

The TSSD® technology can also be used for snap-fit solutions. For this purpose, we offer a variant of the TSSD® with a ball head which - together with a corresponding counterpart (ball socket) - can be used to create a detachable snap-fit connection.

Customized TSSD® variants

If the EJOT TSSD® standard solutions do not meet your application-specific requirements, please feel free to talk to us about special solutions. Whether it's a TSSD® for defining a distance to the component, a snap-fit TSSD® for welding onto thin monolithic materials, a TSSD® for the non-detachable joining of e.g. circuit boards or a TSSD® for holding eccentric connectors, as is common in furniture construction. Please contact our experts for further advice.

![[VBT_EVO_PT].png](/medias/sys_master/products/products/h0d/h92/9356537593886/135Wx135H-.png)