PT®

Specification

-

Overview

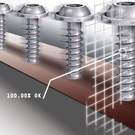

- Special screw for easy and reliable fastening into thermoplastics

- Enables direct assembly to make thin walled and flat designs a reality

- Saves time and work steps

- Minimised radial stress enables thin-walled designs

- High load-carrying capacity due to large thread bearing depth

- Good self-locking of the screw thread

Help, guidance and technical support

Your contacts for industrial fastening systems

EJOT’s advanced fastening systems are found in countless industrial and engineering assemblies around the world. Click below for sales and technical support from one of our experienced team. We conduct inspections and observations onsite, in addition to providing help and advice direct from our UK manufacturing centre.

The pioneer for self-tapping fastening into thermoplastics

EJOT PT® was the first screw of its kind specifically designed for self-tapping fastening into thermoplastics. For decades it has been the benchmark for reliable direct assembly into thermoplastics with application potential in numerous sectors, including automotive and medical appliances. Prior to its development, dynamically and thermally stressed components could not be fastened directly, and only subordinate components were joined using conventional or traditional methods. Designers had to rely on traditional fastening techniques such as screws with metal inserts. PT® changed all this - its design makes thin walled and flat designs achievable, with the potential to deliver material savings and reduced cycle times during injection moulding. The reliability and quality of the PT® joint and the fastening component can, therefore, translate into considerable cost savings overall.

A continuously evolving fastening platform

The design of the PT® screw continues to provide a dependable solution for applications more than 40 years since it was launched. But EJOT never stands still and in response to ever greater demand from design engineers our fastening technology has constantly evolved, upgrading the already excellent characteristics of the PT® screw for optimisation in all details. The result has been the development of the DELTA PT® screw and, more recently, the EVO PT®. Both meet the highest demands for precision and reliability, as well as offering significant application advantages, such as the design support with the EJOT DELTA CALC® prognosis programme.

PT® WN 14 Head Styles and Drives

WN1411 round washer head with cross recess Z (or H)

WN1412 pan head with cross recess Z (or H)

WN1423 flat countersunk head with TORX®

WN1447 hexagon washer head

WN1451 round washer head with TORX®

WN1452 pan head with TORX®

WN1453 oval countersunk head with TORX®

For detailed information, please refer to the EJOT company standard.

You can download these in our service area "CAD & more".

Click here to register: "CAD & more"

![[VBT_EVO_PT].png](/medias/sys_master/products/products/h0d/h92/9356537593886/135Wx135H-.png)