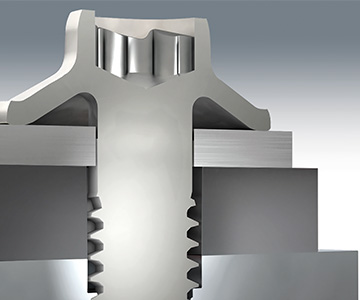

SpringHead®

Specification

-

Overview

- Friction-independent initial clamp load

- Pronounced elastic component in the screw joint

- With the optional washer, stress peaks in the clamping part are reduced

- Significantly improved clamp load retention

Help, guidance and technical support

Your contacts for industrial fastening systems

EJOT’s advanced fastening systems are found in countless industrial and engineering assemblies around the world. Click below for sales and technical support from one of our experienced team. We conduct inspections and observations onsite, in addition to providing help and advice direct from our UK manufacturing centre.

Clamp load retention in case of thermal and dynamic loads

Every screw connection loses clamp load after assembly due to relaxation in the joint. If the clamp load falls below a critical level, the connection fails. These failures can be prevented by increasing the elasticity in the screw connection, e. g. with the integration of spring elements into the screw connection. The innovative EJOT SpringHead® geometry realises this resilient feature and compensates for joint relaxation without additional, conventional spring elements such as conical spring washers. The spring integrated in the screw head enables a better clamp load retention under dynamic and thermal stress as well as a permanent electrical contacting.

Optimal solution for for direct fastening into metals

EJOT SpringHead® is ideal for direct fastening into metals, e. g. with the ALtracs® Xt screw. When the clamping part is made of steel, the SpringHead® can be used without a washer. For clamping parts made of plastic, aluminium or copper, it is recommended to use the SpringHead® with a captive washer for optimum

clamp load retention. Two versions (soft & hard) with different initial clamp load levels are available for each screw size. The EJOT SpringHead® geometry is also compatible with metric threads. Other thread geometries are available upon request.