SHEETtracs®

Specification

-

Overview

- High strength of the screw joint due to the formed draught

- High vibration resistance

- Simple and safe assembly due to good alignment and low installation torque

- High stripping torque due to a robust female thread

- Circular thread cross section for maximised thread engagement

- Metric compatibility

CAD & more - Your Online-Service

* To have access to our CAD data, tools and other services, please register here.

SHEETtracs® CAD data *

Here you can directly download CAD data, PDF and DXF drawings.

SHEETtracs® Application Check *

Our Application Check allows you to make a general statement about the feasibility of your individual joining task.

CAD & more - Your Online Service Area

Unfortunately you currently have no authorization to use "CAD & more".

Unfortunately, this data can not be provided to you without the consent of the confidentiality agreement.

Your request will be manually verified, this can take 1 to 3 business days.

-

For technical questions please contact our Hotline Team +49 2751 529-123

Problems with your access? Mail to: service-industrie@ejot.com

Grant Access to CAD Data

Unfortunately you currently have no authorization to use "CAD & more".

Apply for access to CAD data.

-

For technical questions please contact our Hotline Team +49 2751 529-123

Problems with your access? Mail to: service-industrie@ejot.com

Thank you!

Your request will be manually verified, this may take 1 to 3 business days.

You will receive an e-mail as soon as your access for "CAD & more" has been activated.

Thank you for your patience.

-

For technical questions please contact our Hotline Team +49 2751 529-123

Problems with your access? Mail to: service-industrie@ejot.com

Confirm CAD data renewal

In the e-mail sent by us you will find the link to verify your account, please click on it.

If you do not receive an e-mail within a few minutes, please check your spam folder.

-

For technical questions please contact our Hotline Team +49 2751 529-123

Problems with your access? Mail to: service-industrie@ejot.com

Can not be renewed

Please contact our customer care

-

For technical questions please contact our Hotline Team +49 2751 529-123

Problems with your access? Mail to: service-industrie@ejot.com

Can not process your request for CAD

Please contact our customer care

-

For technical questions please contact our Hotline Team +49 2751 529-123

Problems with your access? Mail to: service-industrie@ejot.com

Help, guidance and technical support

Your contacts for industrial fastening systems

EJOT’s advanced fastening systems are found in countless industrial and engineering assemblies around the world. Click below for sales and technical support from one of our experienced team. We conduct inspections and observations onsite, in addition to providing help and advice direct from our UK manufacturing centre.

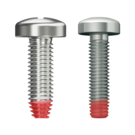

Reliable thin sheet metal joints

EJOT SHEETtracs® supports the goal of designers to continuously reduce the weight and cost of finished manufactured products through the use of thinner sheet materials. Until its development, designers faced the challenge of achieving a secure joint whilst ensuring that the thickness of the components to be connected at least matched the pitch of the sheet metal screws. This issue meant that many types of fasteners used in thin sheet joining quickly reached their limits as sheet thicknesses reduced. The EJOT SHEETtracs® self-tapping screw overcomes this challenge. It features an innovative thread design to make the jointing of pre-punched sheets between 0.5mm and 1.5mm thick a reality. This makes it suitable for a wide range of applications and a few typical examples include white goods, automotive, aerospace, lightweight construction and assembly.

Innovative thread design

EJOT SHEETtracs® eliminates the need to use a metric 60° thread screw, which can represent a weak point in the joint as a result of the female thread it forms. Instead, the self-tapping screw features a 45° (30° / 15°) asymmetric flank angle designed to displace material to create a stronger female thread in the sheet. The stripping torque level of the joint is increased, and multiple repeat assemblies are possible. In the lower, tapered area of the screw, the flank angle is reversed, and the resulting through draught is formed mainly into fastening direction. The non-circular thread forming zone ensures easy, centred application and the raised thread areas ensure a secure penetration of the sheet material. The circular cross section in the upper, load bearing thread results in higher thread engagement in the sheet metal compared to non-circular thread geometries.

SHEETtracs® Application Check

The EJOT SHEETtracs® is a self-tapping screw for reliable thin sheet metal joints with pilot hole. Check that it is right for your application with our online tool – the SHEETtracs® Application Check. This enables the relevant values for the fastening application to be determined by entering the materials and sheet thicknesses which are to be joined. These values are, amongst others, the required pre-hole diameter and a recommended tightening torque considering different screw surfaces.

SHEETtracs® WN 52 WN54 Head Styles and Drives

- WN5241 round washer head with Z cross recess (or H)

- WN5242 pan head with cross recess Z (or H)

- WN5243 flat countersunk head with cross recess Z (or H)

- WN5247 hexagon flange head

- WN5251 round washer head with TORX®

- WN5252 pan head with TORX®

- WN5254 flat countersunk head with TORX®

For detailed information, please refer to the EJOT company standard.

You can download these in our service area "CAD & more".

Click here to register: "CAD & more"