High Corrosion Resistance anchors a perfect fit for major UK road tunnel building project

Road tunnels present a major challenge to metal fastening systems of all kinds given the highly corrosive atmosphere that is present within them. But where mechanical anchoring is concerned, specifiers and engineers can comfortably achieve their performance and durability goals in these demanding environments as a recent project by EJOT UK demonstrates.

The installation of the electrical services and public address (PA) system in one of the UK’s most high-profile new road tunnel projects involved the installation of more than 6,000 high performance mechanical anchors.

Tasked with providing these anchors was EJOT UK. They supplied EJOT and LIEBIG branded HCR (high corrosion resistance) anchors for the major civil engineering project to BISON UK, who are a nationwide market-leading supplier of fixings, support systems and bracketry to the M&E and building engineering services sectors.

Ready-made solutions, ready-made for corrosive environments

The company approached EJOT UK for an anchoring solution that could be deployed throughout the new tunnel’s main bore and separate under-tunnel - beneath one of the UK’s most significant waterways - to meet the demanding performance specification required for the highly corrosive environment. At the same time, BISON also sought to ensure the solution would enable the main contractor to keep the project on track and on budget by avoiding the lengthy lead times and high unit costs often associated with such products.EJOT’s UK anchoring team was able to meet the requirements of the brief with maximum efficiency. They recommended two products from its portfolio – the EJOT BA-E Plus HCR through-bolt manufactured in 1.4529 high corrosion resistance stainless steel, and the LIEBIG Superplus BLS-P self-undercutting heavy duty expansion anchor manufactured in A4 stainless steel.

Understanding applications demands through dedicated support

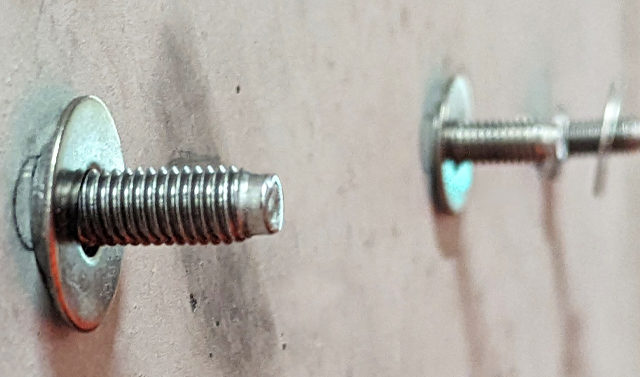

The BA-E Plus 10/10 HCR through-bolt anchors specified have been used to securely attach the bracketry for the electrical system trays throughout the tunnel development. EJOT was able to provide a bespoke version of this versatile 120-minute fire-rated through-bolt which features an additional washer to offset the brackets from the tunnel wall and prevent moisture collecting. A special tool was also supplied by EJOT to enable easier overhead installation of the anchors.Vibration resistance an added benefit

Bespoke LIEBIG Superplus BLS-P anchors in two different lengths were specified for use in stand-off applications that included speakers and other components associated with the tunnel’s PA system. These anchors met a slightly different brief in that they were also required to demonstrate a high level of vibration resistance resulting from vehicle flow through the tunnel. The PA system bracketry then utilised the anchors two lengths to accommodate the size and shape of the speakers in the context of the tunnel’s curved walls.Bill Browning, Business Development Director at BISON UK, said: “The combination of exhaust emissions from vehicles and the moisture laden air, given the close proximity to the water, demanded anchors with a high degree of corrosion resistance, and it was clear that the EJOT and LIEBIG products recommended by EJOT’s anchoring specialist consultants would achieve the performance specification.

“But it was also imperative that these could be provided within relatively short lead times and to a strictly controlled budget, and here the EJOT package met the brief without compromise. The EJOT team provided all the technical data necessary to demonstrate that both the BA-E Plus and Superplus BLS products would perform in-situ, with the added assurance of European Technical Assessments (ETAs), and enable fast, efficient installation.

“And because of the way their business is set-up, they could offer the flexibility we required to accommodate the bespoke anchor design and smaller volumes involved in this project.”

Both the anchors supplied by EJOT for this tunnel project are designed for use in cracked and non-cracked concrete where only a relatively shallow embedment depth is possible. They provide medium to high load capacity in a diverse range of applications including nuclear facilities and industrial plants.